Common and typical DLC applications

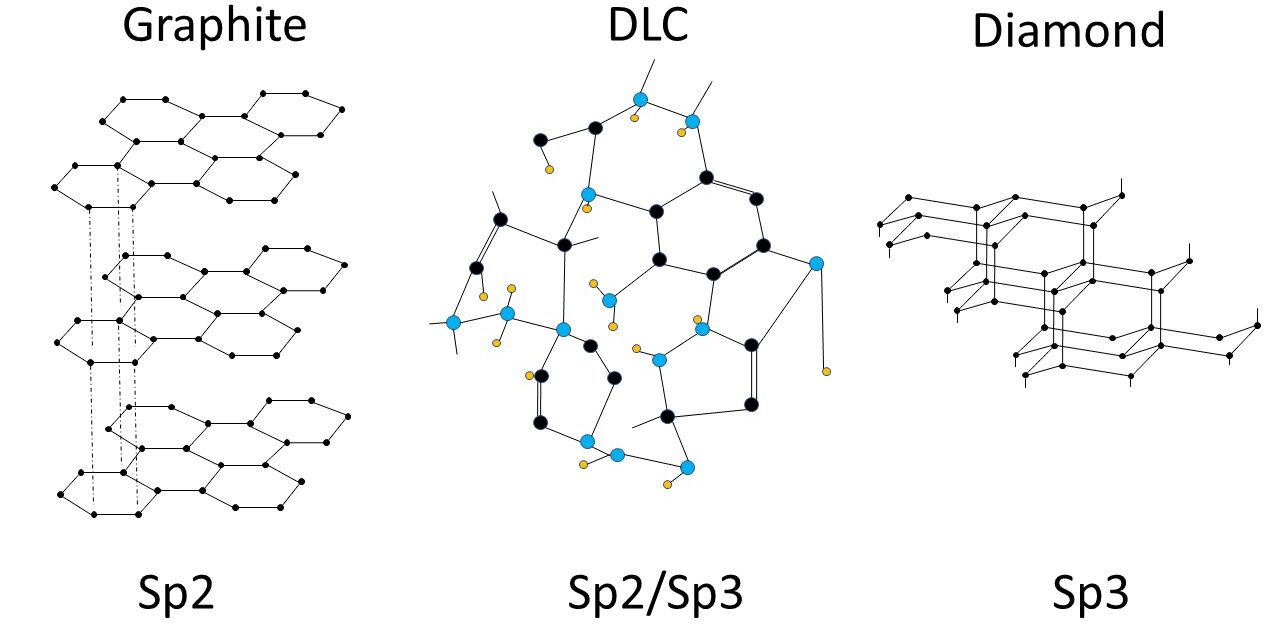

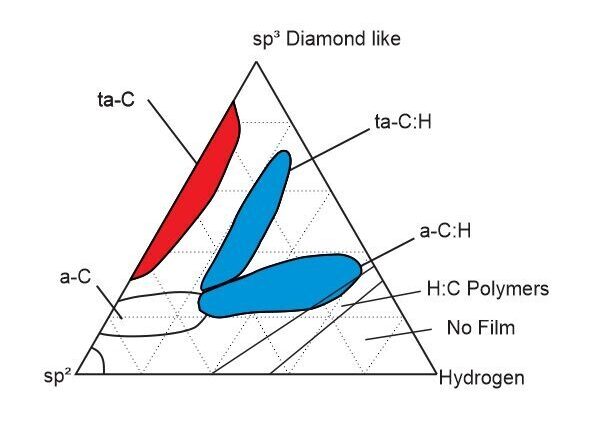

Looking at the ternary diagram one quickly understands that altering the sp2, sp3 and h fractions of the DLC film will create a coating that is either diamond like, graphitic or polymeric. The applications are therfor endless. High uniformity and pinhole free films available as well as metal rich DLC. Here's a few we love to share.

Drivetrain components

High hardness and low friction reduces the required torque and power. Adding DLC to the fingers and cams further reduces friction. High aspect ratio process to fill cavities 10:1 available

Ophthalmic hydrophobic VIS

Proprietary proccess creates a very flexible DLC that binds directly to glass and most plastics. Diluted and post processed for max hydrophobicity

High temperature iDLN™

Arguably the hydrogenated Si:O rich DLC with the highest sp3 fraction available on the market. Combining high hardness, low COF and extremely low wear rate. Available as dielectric or semi conductive

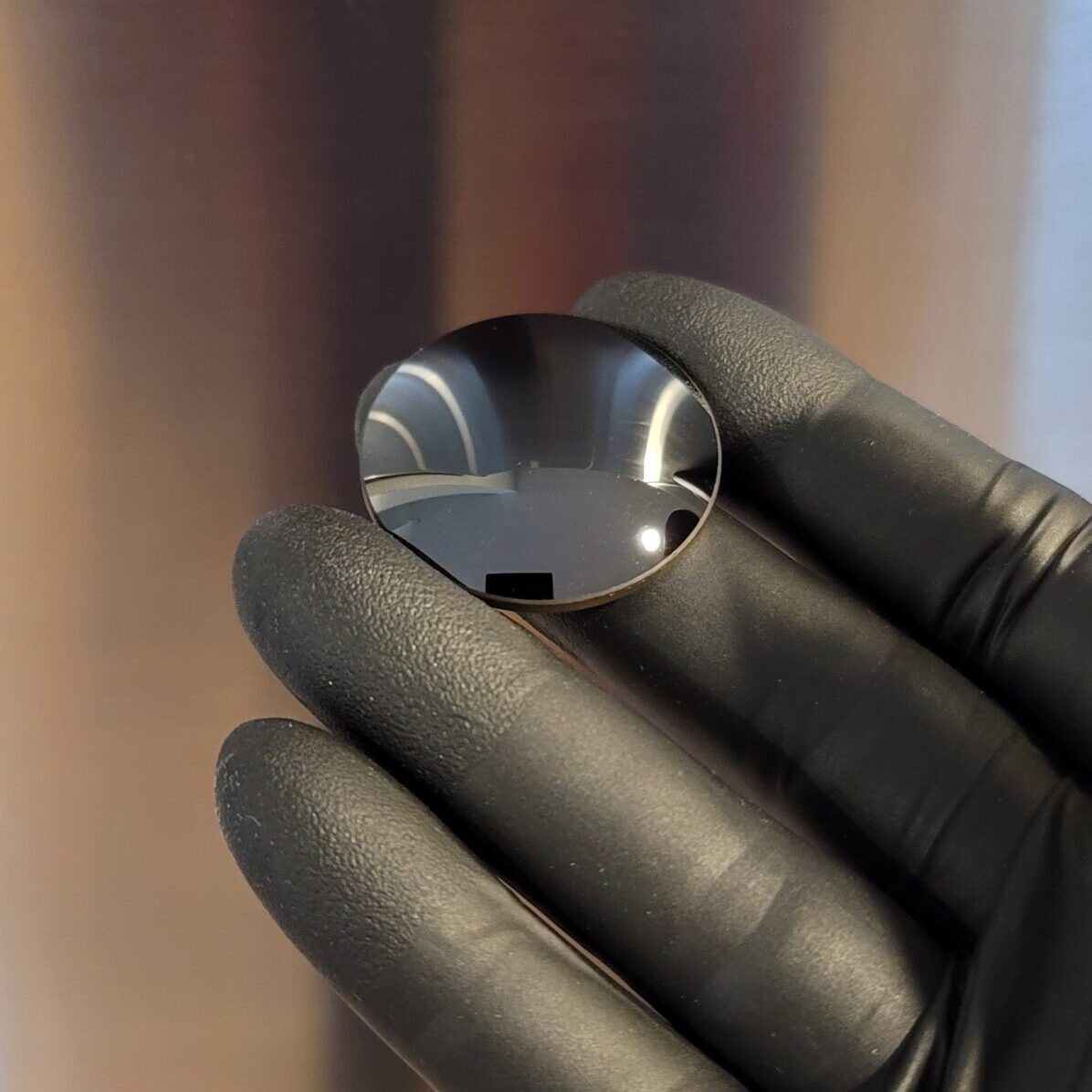

Precision optics DLC

Your ticket to MWIR and LWIR on Germanium, ZnS, ZnSe and Chalcogenide glas. Our unique process controls guarantees perfect adhesion and MIL-C properties

Flexible DLC

DLC is know to be hard but brittle. For those applications where continuous flexibility is required we developed a DLC withstanding thousands of folds or bends not limited by the bend radius. Typical applications include plastics, foils and wire, cord or wire meshes. This process allows to be modified with a variety of additives. Thermal and Electrical conductivity are adjustable if one requires such need.