Custom-designed to enhance coating quality

and streamline throughput

Optimizing for your specific application

The carousel is a central and vital part of most coating systems, and its design can have a major impact on the quality of coating and ease and efficiency of operation – as well as the overall throughput.

This is why Thin Film Service places a great deal of attention on designing and optimizing the carousel for the specific needs of the user’s coating and application.

Examples of our specially-optimized carousels…

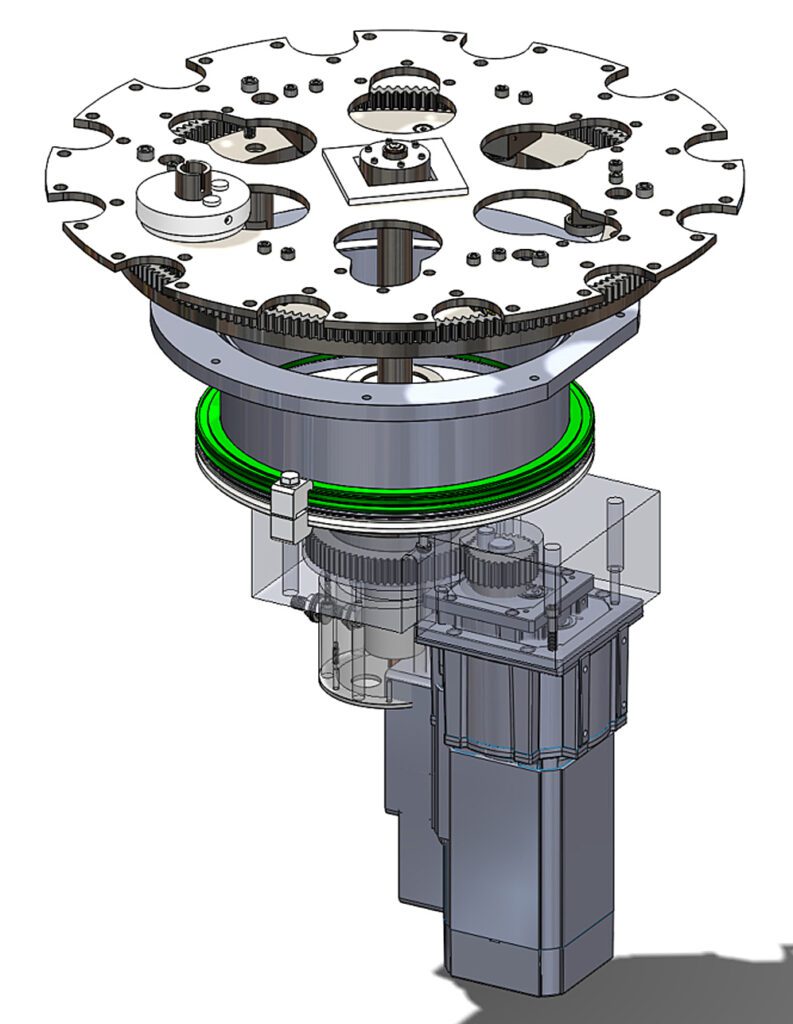

High Capacity

Often used for large vacuum coating of thousands of parts. Offers two circumferences, for smaller or larger parts. Each position can be biased for DLC or substrate cleaning along with PVD deposition.

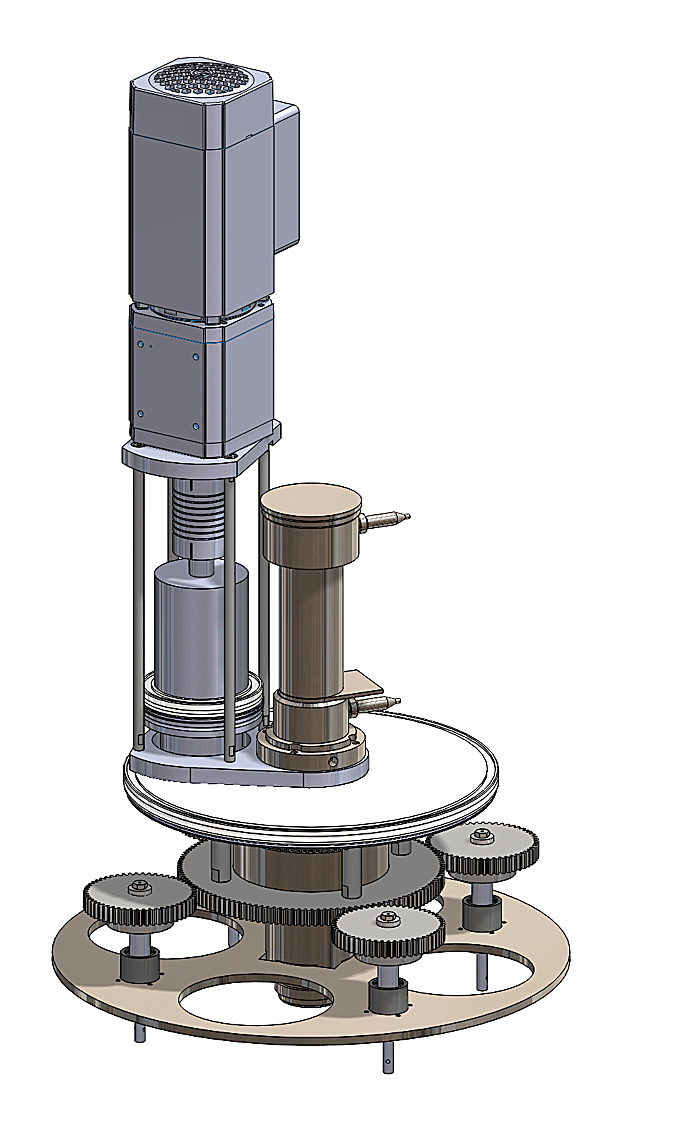

Optics

Typically used for optics. Substrate not biased. For PVD only. Four positions. Hollow center shaft contains an optical monitor system to measure/validate deposition in situ.

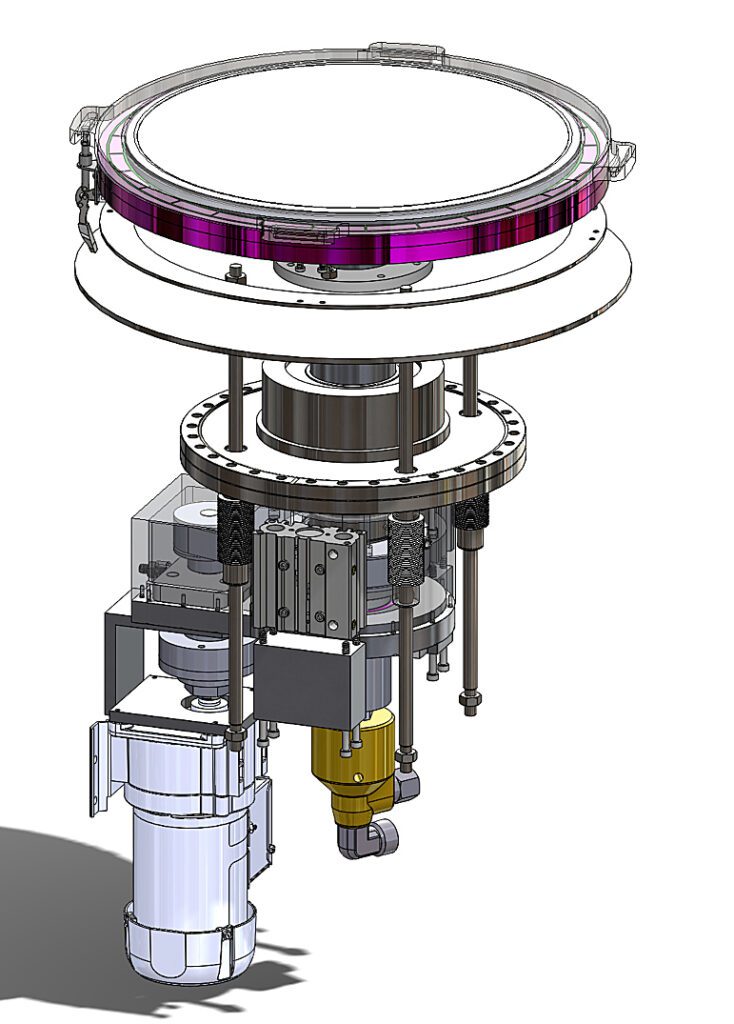

Temp Control

This high-end carousel provides precise temperature control and optical uniformity. Substrate can move up and down to vary distance to source. Substrate can be heated or cooled. Substrates may be grabbed and offloaded onto a loading arm.

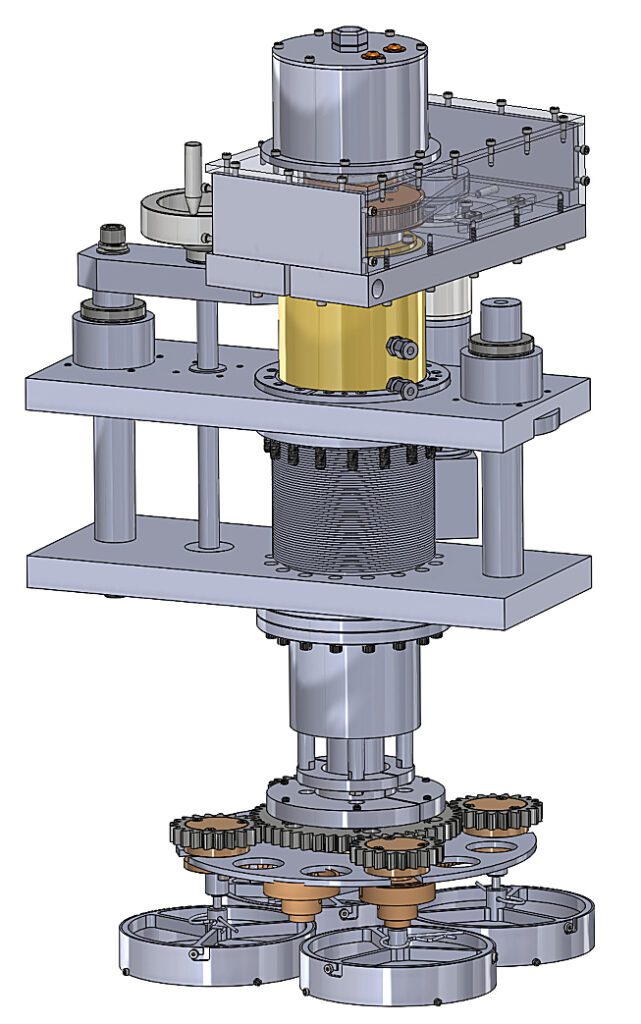

RF Biased

This often-used RF-biased

carousel provides

four satellites and allows

for 150mm vertical

adjustment.