Applying Our Decades of Experience

To Optimize a New Custom Thin Film System for You

Co-Engineering Your New Coating System

Applying our specialized thin film expertise and proprietary IP

to your unique requirements

Covering all the possibilities

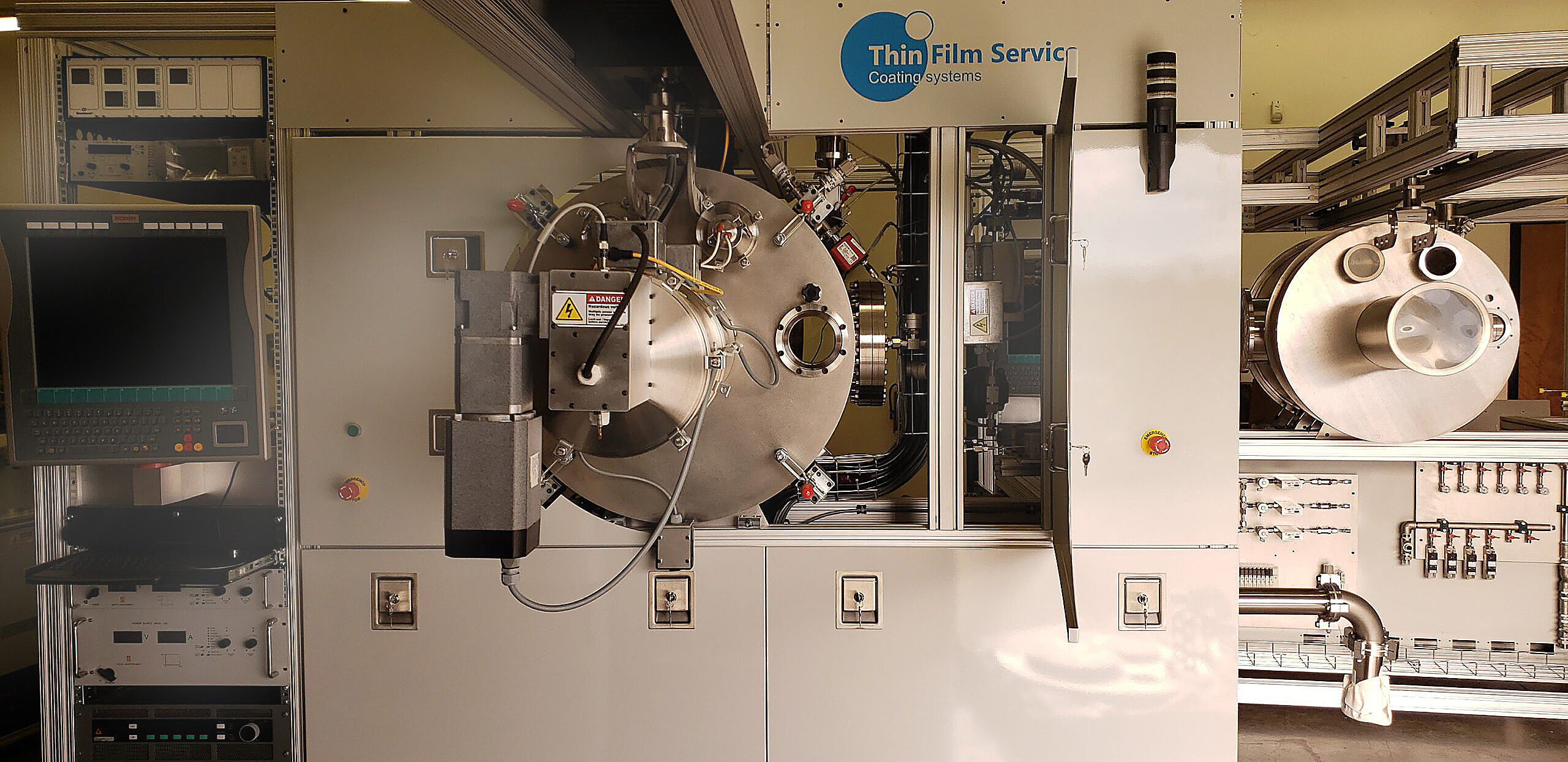

For your new coating system, Thin Film Service is able to help with literally everything from inception to FAT, SAT, and SOP. That includes assistance with a broad range of ancillary functions such as UL or CE certification. Thin Film Service is a full-service engineer-to-order manufacturing company that is uniquely specialized in diamond and ceramic coatings, for IR optics, high-current ION etch, PVD, MCA, ESC semiconductor, and much more.

We can deliver highly specialized advanced coatings and coating systems for a range of materials including plastic films, glass, ceramics, metals, and more. We can deliver anti-wear, low-friction, and durable coatings specifically customized to enhance flexibility, hydrophobic, and temperature-resistance qualities. So, whether you need CVD or PVD coating technology – mid-frequency, pulsed DC, or RF magnetron sputtering, we can help.

Note too that we serve companies of all sizes, and everything we do is designed to ensure easy production, reduced downtime, and minimized waste.

Working hand-in-hand with you

In working with you, we begin by immersing ourselves in your specific coating application, objectives, and requirements. We know that you understand your application and needs better than anyone, so we want to take the fullest advantage of all your information and experience.

Next, we analyze how we can best add value to your new system’s design and development – what proprietary IP or special approaches or methodologies we have developed might help to optimize processes and results for your particular needs. Our years of experience cover a broad range of industries and coatings, including tribological, optical, semiconductor, display, medical, automotive, aeronautical, solar, and much more. And the special insights we have gained uniquely enrich our abilities to innovate and optimize all our ongoing work.

A nimble, vertically-integrated, rapid process

As we enter into the active design and development of your special new coating system, everything is done in close coordination with you, including testing and optimizing each essential element each step of the way. We keep you closely involved continuously, integrating all of your contributions and feedbacks on an ongoing basis, making certain that everyone is always fully informed.

Along with our specialized thin film technology experience and IP, our special structure provides all the advantages of full vertical integration. This includes such capabilities as having all the necessary specialized metrology in-house.

The net results are significantly faster turnarounds and superior results – from initial concepts to finished, optimized solutions.

Our commitment to safety

Every Thin Film Service product leaves our factory with either a UL label and/or a CE label. Unlike European OEM’s who can self-certify, here we apply 8D (Eight Disciplines) and use Safexpert along with an external regulatory body for our CE compliance where the highest safety level or performance level e (Pl e) is assured according to ISO13849-1.

Taking care of all the details

In every detail, we are committed to the safety and well-being of the operator and user. For example, our liquid precursor vessels are free of sight glass and made of double-walled stainless steel using magnetic level detection. Months of R&D have gone into the design of our pressurized vessels which contain no sight glasses or plastics that are vulnerable to breakage or leakage. Fill height is in full compliance with international standards regarding machine safety.